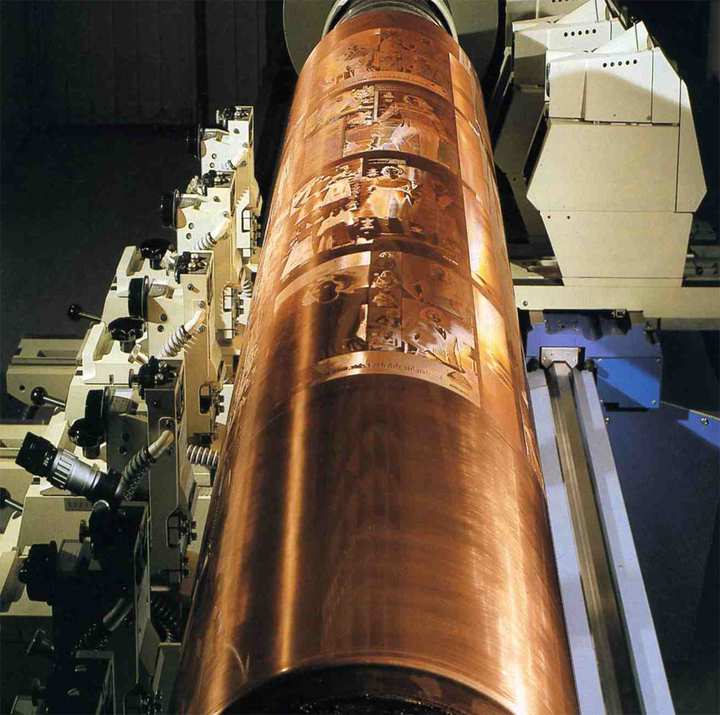

| Klischograph K 155 |

||||||

|

By the Klischograph, the image is scanned line-by- line and with the electrical signal derived therefrom, a steel stylus is actuated which, depending on the gray value of an image point, engraves a more or less large depression into a plastic plate or a metal plate. This results in a rasterized letterpress or gravure print plate.

Klischograph K 155 catalogue 1972 (German)

|

||||||

|

The material to be engraved is attached to the engraving drum (right), the image template is mounted on the scanning drum (left). During the engraving process, the scanning head and the engraving head move toward one another, so that the printing forme is automatically mirror-inverted engraved as required for printing. The scale is determined by the circumference of the scanning drum and the feed speed of the scanning head. The following fixed standards are available:

180%, 130%, 100%, 80%, 65%, 50%

|

||||||

|

Restoration of K 155 within June 2017 |

||||||

|

|

||||||

|

|

||||||

| The song about Klischgraph | ||||||

|

||||||

|

||||||